- Home

- >

- Products

- >

- High Voltage Equipments

- >

- Industrial Electron Accelerator Equipments

Industrial Electron Accelerator Equipments

Brand :HVDIODE

Product origin :CHINA

Delivery time :180 TO 270 DAYS

Supply capacity :10

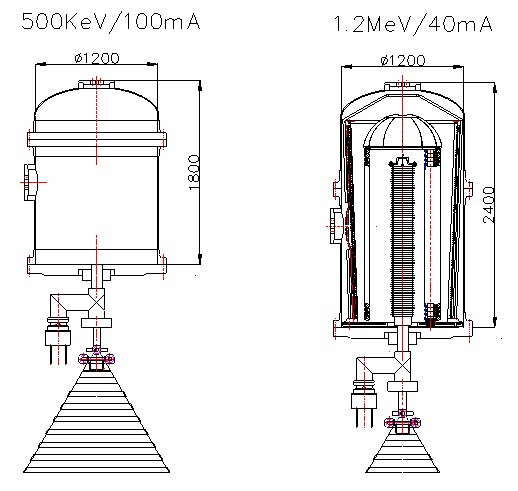

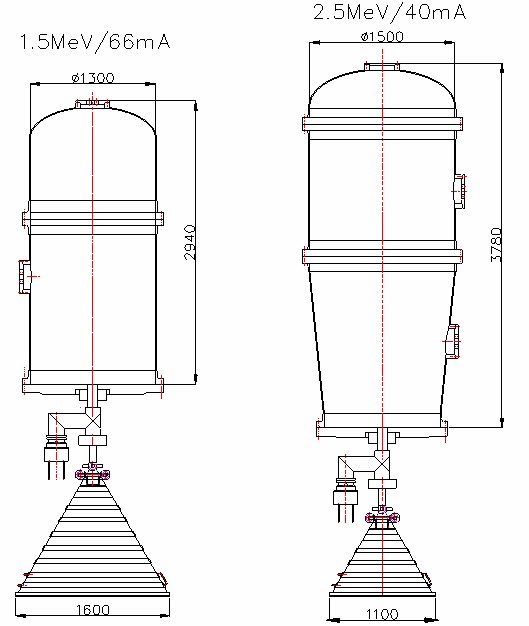

Transformer Type Electron Accelerator/Radiation Processing;

Low Energy Consumption,High Efficiency;

Power Saving for Five Years Equivalent to earn one accelerator again;

The Application of Radiation Processing:Material of cross linking、grafting,curing and splitting;

Supply the whole accelerator, traditional system;

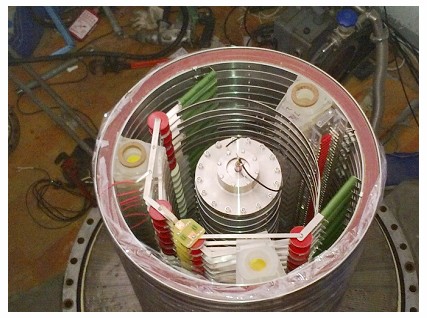

Supply accelerating tube, electronic gun, secondary coil and son on;

Can be customized according to the requirements of the industry。

Efficient Energy Using: The E-beam irradiates on the products, then the product area will be in even distribution;

Effective Absorption: The E-beam technology makes it can be absorbed in the most and less waste in the air;

Easy to Operate and Control;

Operation Security。

High Voltage Test Equipment, High Voltage Measuring Instruments

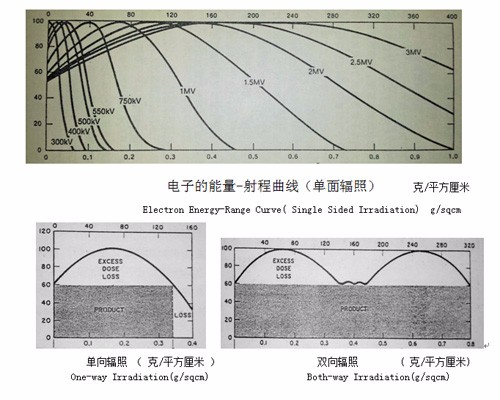

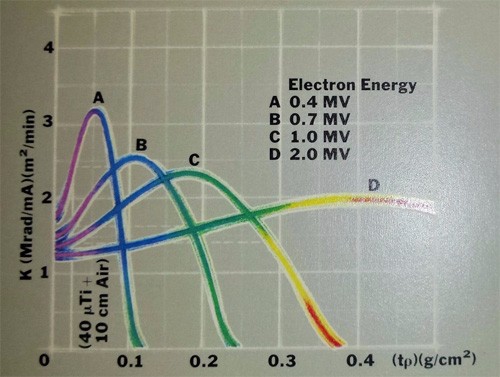

1MeV Energy of Electron Irradiation Processing Thickness:

Irradiation processing capacity of E-beam depends on the E-beam energy, High Voltage Test Equipment beam intensity and required dose of material.

Irradiated object thickness t(cm) is decided by energy, above penetration depth of abscissa to divide by material density. High Voltage Equipments The penetration depth of electron for 1MeV energy is 0.33cm(One-way Irradiation) or 0.8cm(Both-way Irradiation).

Production capacity (m2/min)= f * K * I / D, I is beam intensity (mA), D is required dose of material(Mrad).K is the area productivity of irradiation processing(Mrad/mA)(m2/min, f is the beam utilization, High Voltage Measuring Instruments take 80% to 90%.

Energy(MeV) 0.4 0.7 1.0 2.0

K 2.45 1.5 1.18 1.0

The Application of Radiation Processing

(1). Radiation crosslinking wire: Power/control/instrument Temperature-resistance/Abrasion resistance/Oil resistance/Crazing resistance/radioresistance Pyrocondensation material:Tube/coating stripe Fork set of cable connection.

(2). The early stage of vulcanization for tyre Irradiation film high quality uni-cross section film reduce scrappage/saving materials/weight reduction.

(3). Radiation crosslinking foamed polyethylene/polypropylene material uniformity/closed pore structure easy to control foam density/pore size/ pore structure.

(4). Printing solidification for food containers

(5). Surface curing for the building materials

(6). Sterilization for medical instruments

(7). PTFE dissociation/nano-scale particle/power plant. high grade lubricant/NBR dissociation/regeneration of waste tires/irradiation crosslinking plastic film, ring/enhance strength

(8). desulfurization and denitrification of coal-fired /increase 2 cents per kilowatt-hour/efficient E beam method can reach to desulfurization 95% and denitrification 80% at the same time/ by-product is ammonia fertilizer/cost 30% lower than regular wet desulfurization, operating cost 20% lower

(9). Food irradiation/ kill eggs

(10). irradiation breeding

RECOMMEND PRODUCTS

Industrial Electron Accelerator Equipments